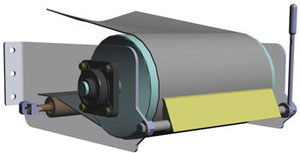

KAWE Conveyor Belt Cleaner – New Generation

Especially in industry, time is of the essence. Therefore, losing time because a conveyor belt is dirty and needs cleaning is not only annoying because it stops the whole production chain, it also causes financial losses. Consequently, an easy cleaning solution is essential. The KAWE conveyor belt cleaner provides an effective and easy-to-install answer. Lightweight and relatively low-maintenance, it can be easily integrated into existing processes. The KAWE belt cleaner is perfect for industrial use.

The new conveyor belt cleaner system developed by KAWE is already used in following industries:

- Sand mining

- Concrete/Gravel production

- Sawmills

- Salt production

In response to an industry requirement, we have developed an all-new conveyor belt cleaner for the food sector.

Quick and easy solution: The KAWE belt cleaner

Our conveyor belt cleaner is the perfect tool for reliable cleaning. It complies with the test report in accordance with Commission Regulation (EU) No. 10/2011 of January 2011 on plastic materials and articles intended to come into contact with food. This makes it ideal for use in food production. Thanks to its capabilities, it can also be used as an under-belt cleaner. Our cleaner offers you the following advantages:

• superior hygienic standard

• minimal production loss

• little maintenance effort required (especially cleaning)

• easy installation

• all components from stainless steel and food-grade polyurethane (FDA-approval)

• highly resistant to oil, fat and solvents

• suitable for use within a large temperature range

• constructed to prevent the danger of any single component loosening and contaminating the product

• hingeable from the belt surface, which allows quick and easy cleaning without the need for additional tools

• high wear resistance and minimal belt wear even under dry run conditions

• available in many different sizes to suit your installation (up to 1800 mm)

• deliverable for convex driving rolls

• installable with minimum effort

Perfect belt cleaning for industrial use

Our conveyor belt cleaner is based on a unique polyurethane (FDA-approval) developed by KAWE. Its properties allow for perfect sliding and provide a very dynamic capacity, good resilience and resistance to wear and tear, weathering and UV radiation. This guarantees a long-term solution and prevents product contamination from mechanical damage. Therefore, our belt cleaning solution is a flexible and reliable addition to your conveyor belts.

What you need to look for during installation

When installing our conveyor belt cleaner, it is important to set the correct pressure to achieve the best cleaning results. KAWE has developed a special maintenance-free torsion element, located in the axle tube. This not only saves you a lot of space, it also protects the torsion element against external influences such as dirt or product residue. Consequently, the cleaning belt is easy to work with.

Easy assembly of your conveyor belt cleaner

Installing a belt cleaner can be hard and time consuming. Therefore, we constructed ours with ease of installation in mind. Most of the time there is no need for changes to the conveyor belt or the hopper. This depends on the on-site construction. If the cleaner needs to be reallocated after an “on-site assembly”, this can be carried out easily by twisting the eccentric counter bearing.

Setting of the scraping pressure

If you need to adjust the scraping pressure, simply loosen the two fastening screws and move the torsion element into the required position. This makes our conveyor belt cleaner extremely user-friendly.

Simple way of cleaning

If a cleanup is necessary, you can easily use a hand lever to flap the belt from the surface. This makes cleaning so much easier than with other solutions.

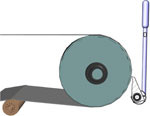

Installation options for your belt cleaner

Our conveyor belt cleaners are very flexible and therefore can be used with different belt sizes. They are most often used as head oder drum scrapers, but other options are also possible. The installation process is very easy and does not take long.

The ideal position depends on the product and the belt being used. If the scraped product is supposed to remain within the production flow and be further transported, the scraper position needs to be like mounting position 1 (see picture).

If the scraped product is supposed to be separated from the main stream, the scraper position needs to be similar to mounting positions 2 or 3.

The hinge moment, which emanates from a supporting tube located behind the scraper, is being transmitted to the scraper via corresponding levers. The hinge moment can be set individually, like for the standardized scraper.

In addition to our standardized scraper, we also offer our universal scraper. If you need to clean difficult-to-remove elements like sugar icing from your conveyor belt, this product is for you. The universal scraper is manufactured with a supporting axis instead of a supporting tube.

Easy belt cleaning solution by KAWE

The flexibility our belt cleaners offer is unparalleled. That’s because our goal was to create a product that could be used effectively in as many sectors as possible. From food production to wastewater purification or even brick manufacturing: Our conveyor belt cleaning solutions offer many possibilities. If you have any questions, we are happy to assist you. This innovative belt cleaner shows that a flexible yet efficient solution is possible.

Depending on the application, various wear segments made of polyurethane, ceramic or carbide are available. Your experts at KAWE will be happy to advise you on which scraper for conveyor belts offers the ideal solution for your application. If you want to replace the segments, either to use a different material or because the previous one has weathered, you can easily do so without much expertise.

Do you have any questions about our belt scraper or would you like to test it for free?

KAWE industry scraper for all applications

The KAWE belt cleaner is an effective and flexible conveyor belt cleaning solution. It can be integrated into existing systems and is easy to install and maintain. Depending on your specific

needs, you can choose from three variants: polyurethane, hard metal and ceramic. These can be easily switched out when needed. The cleaning not only ensures hygienic conditions, it also lowers

the maintenance costs of your conveyor belt.

- Painted steel

- Stainless steel - 1.4301

- A4 - 1.4571

- Aluminum

Customer-oriented belt cleaner systems with high efficiency

If you want to optimize your production processes with effective belt cleaning, a scraper for the conveyor belt from KAWE is the right choice. Our scraper systems are available in various heights and widths, and we also offer versions for crowned deflection rollers on request. Our belt cleaners can be fitted during commissioning or added to existing machines later. The belt is protected by an excellent sliding and wear process. The technology protects the belt from contamination and keeps it clean for use in production, even under high-load conditions. Our cleaner therefore ensure a long service life with low maintenance requirements.

Would you like to find out more about our belt cleaner? We will be happy to advise you individually and are also available to answer your questions at any time!

You want to read more news about KAWE?

..please have a look